QUANLITY ASSURANCES?

As a professional manufacturer of faucets and bathroom accessories, DEEPSS adheres to the promise of excellent quality and integrates high quality into every product detail.

Our production process is at the core of our quality assurance. From raw material procurement, design, manufacturing, to strict quality inspection, every step is strictly monitored and checked.

HOW DEEPSS FAUCET MANUFACTURING PROCESS?

Raw material storage

The brass has high quality purity, we strictly control copper purity with 58%-62% in level A of low lead for healthier life. The thickness is 3mm, which will reduce the sand hole so the products will not leak.

Sand mould process

Make sure the smoothness, to avoid sand holes as less as it can after casting.

Gravity casting

Comparing to old process by sand casting, gravity casting is better keep a certain high temperature, to make sure bodies are not out of shape and keep the same thickness.

After gravity casting, the body will go through the first water test, to flush out the sand and test by air pressure to prevent the leakage on body if caused by sand hole.

CNC machine

After casting we would do this CNC machining process. Including this important technical process-peeling steps on rough casting surface, for precise evenness and smoothness.

Polishing

DEEPSS adheres rigorously to a sequence of five meticulous stages: initial rough polishing, subsequent fine polishing, finishing with over 400 grit, advancing to over 800 grit, and culminating in a thorough clearing process. Each faucet undergoes a methodical step-by-step polishing regimen, employing cloth wheel polishing to ensure a superior level of smoothness for our products.

WATER TEST

Flushing the faucet body, to make sure there’s no debris inside. Then we will do the water test again in 2nd time to make sure no leakage.

ASSEMBLING

Focusing on providing high-quality faucet assembly services. With exquisite technology and on-time delivery as our belief, we meet your needs.

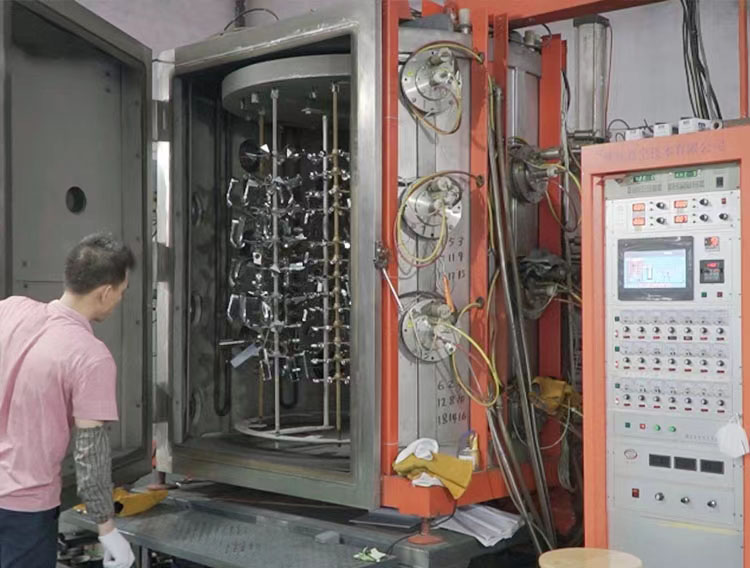

SURFACE TREATMENT

DEEPSS has 8 years of color experience, and the color has considerable stability and durability.

LAB TEST

We will test the flow rate for different countries to meet different standards. We make the record everyday, all the dates will show in the computer.

Acid salt test for 24 hours and 48 hours. If not qualified, there are rusted spots appeared.

LIFE TEST

After undergoing continuous 3 months of durability and life testing for over 500,000 cycles, the cartridge remains in perfect working, fully meeting the 5 years quality warranty.

Get A Free Quote Now?

Not sure what you need? Fill in the information to get our most popular faucet list directory.